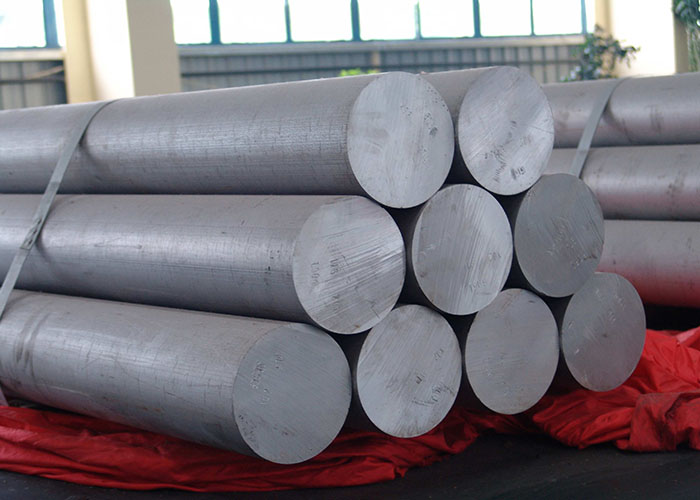

6061 (Unified Numbering System (UNS) designation A96061) is a precipitation-hardened aluminium alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S", it was developed in 1935. It has good mechanical properties, exhibits good weldability, and is very commonly extruded (second in popularity only to 6063). It is one of the most common alloys of aluminium for general-purpose use.

It is commonly available in pre-tempered grades such as 6061-O (annealed), tempered grades such as 6061-T6 (solutionized and artificially aged) and 6061-T651 (solutionized, stress-relieved stretched and artificially aged).

Chemical Composition of Aluminum 6061

Spec: BS EN 573-3:2009

Alloy 6061

Chemical Element % Present

Manganese (Mn) 0.0 - 0.15

Iron (Fe) 0.0 - 0.70

Magnesium (Mg) 0.80 - 1.20

Silicon (Si) 0.40 - 0.80

Copper (Cu) 0.15 - 0.40

Zinc (Zn) 0.0 - 0.25

Titanium (Ti) 0.0 - 0.15

Chromium (Cr) 0.04 - 0.35

Other (Each) 0.0 - 0.05

Others (Total) 0.0 - 0.15

Aluminium (Al) Balance

Properties of Aluminum 6061

Physical Property Value

Density 2.70 g/cm³

Melting Point 650 °C

Thermal Expansion 23.4 x10^-6 /K

Modulus of Elasticity 70 GPa

Thermal Conductivity 166 W/m.K

Electrical Resistivity 0.040 x10^-6 Ω .m

Spec: BS EN 755-2:2008

Extrusions - Up to 200mm Dia. & A/F, 5mm WT for Tube and Prof

Mechanical Property Value

Proof Stress 240 Min MPa

Tensile Strength 260 Min MPa

Hardness Brinell 95 HB

Svojstva

The mechanical properties of 6061 depend greatly on the temper, or heat treatment, of the material. Young's Modulus is 69 GPa (10,000 ksi) regardless of temper.

6061-O

Annealed 6061 (6061-O temper) has maximum ultimate tensile strength no more than 150 MPa (22 ksi),and maximum yield strength no more than 83 MPa (12 ksi) or 110 MPa (16 ksi). The material has elongation (stretch before ultimate failure) of 10–18%. To obtain the annealed condition, the alloy is typically heated at 415 °C for 2-3 hours.

6061-T4

T4 temper 6061 has an ultimate tensile strength of at least 180 MPa (26 ksi) or 210 MPa (30 ksi) and yield strength of at least 110 MPa (16 ksi). It has elongation of 10-16%.

6061-T6

6061-T6 aluminium standard heat treating process

T6 temper 6061 has been treated to provide the maximum precipitation hardening (and therefore maximum yield strength) for a 6061 aluminium alloy. It has an ultimate tensile strength of at least 290 MPa (42 ksi) and yield strength of at least 240 MPa (35 ksi). More typical values are 310 MPa (45 ksi) and 270 MPa (39 ksi), respectively.[10] This can exceed the yield strength of certain types of stainless steel.[11] In thicknesses of 6.35 mm (0.250 in) or less, it has elongation of 8% or more; in thicker sections, it has elongation of 10%. T651 temper has similar mechanical properties. The typical value for thermal conductivity for 6061-T6 at 25 °C (77 °F) is around 152 W/m K. The fatigue limit under cyclic load is 97 MPa (14 ksi) for 500,000,000 completely reversed cycles using a standard RR Moore test machine and specimen.[12] Note that aluminium does not exhibit a well defined "knee" on its S-N curve, so there is some debate as to how many cycles equates to "infinite life". Also note the actual value of fatigue limit for an application can be dramatically affected by the conventional de-rating factors of loading, gradient, and surface finish.

6061 is commonly used for the following:

construction of aircraft structures, such as wings and fuselages, more commonly in homebuilt aircraft than commercial or military aircraft. 2024 alloy is somewhat stronger, but 6061 is more easily worked and remains resistant to corrosion even when the surface is abraded. This is not the case for 2024, which is usually used with a thin Alclad coating for corrosion resistance.

yacht construction, including small utility boats.

automotive parts, such as the chassis of the Audi A8 and the Plymouth Prowler.

flashlights

aluminium cans for the packaging of food and beverages.

Scuba tanks and other high pressure gas storage cylinders (post 1995)

Equivalent materials

6061 Aluminium Equivalent Table

| US | Europska unija | ISO | Japan | Kina | |||||||

| Standard | Grade (UNS) | SAE AMS Standard | Razred | Standard | Numerical (Chemical Symbols) | Standard | Razred | Standard | Razred | Standard | Razred |

| AA;ASTM B209; ASTM B211; ASTM B221; ASTM B210; ASTM B308/B308M; ASTM B241/B241M | 6061 (UNS A96061) | SAE AMS 4025;SAE AMS 4026; SAE AMS 4027; SAE AMS 4117 | 6061 | EN 573-3 | EN AW-6061(EN AW-AlMg1SiCu) | ISO 209 | AW-6061 | JIS H4000;JIS H4040 | 6061 | GB/T 3880.2GB/T 3190 | 6061 |

Standardi

Different forms and tempers of 6061 aluminium alloy are discussed in the following standards:

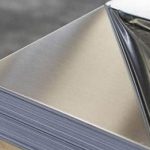

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- ASTM B210: Standard Specification for Aluminum and Aluminum-Alloy Drawn Seamless Tubes

- ASTM B211: Standard Specification for Aluminum and Aluminum-Alloy Bar, Rod, and Wire

- ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

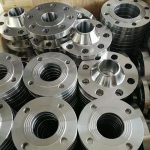

- ASTM B308/308M: Standard Specification for Aluminum-Alloy 6061-T6 Standard Structural Profiles

- ASTM B483: Standard Specification for Aluminum and Aluminum-Alloy Drawn Tube and Pipe for General Purpose Applications

- ASTM B547: Standard Specification for Aluminum and Aluminum-Alloy Formed and Arc-Welded Round Tube

- ISO 6361: Wrought Aluminium and Aluminium Alloy Sheets, Strips and Plates